Disclosure: This post may contain affiliate links. I earn a small commission when you click a link and make a purchase. Thanks for supporting SewingSociety.com!

If you’re new to sewing, you might not realize that there are many different types of sewing machine needles. Each has a different purpose and is suited to a different fabric. That means you shouldn’t just use a universal needle for everything you sew — yes, it really does matter. In this post, I’ll walk you through everything you need to know about sewing machine needles!

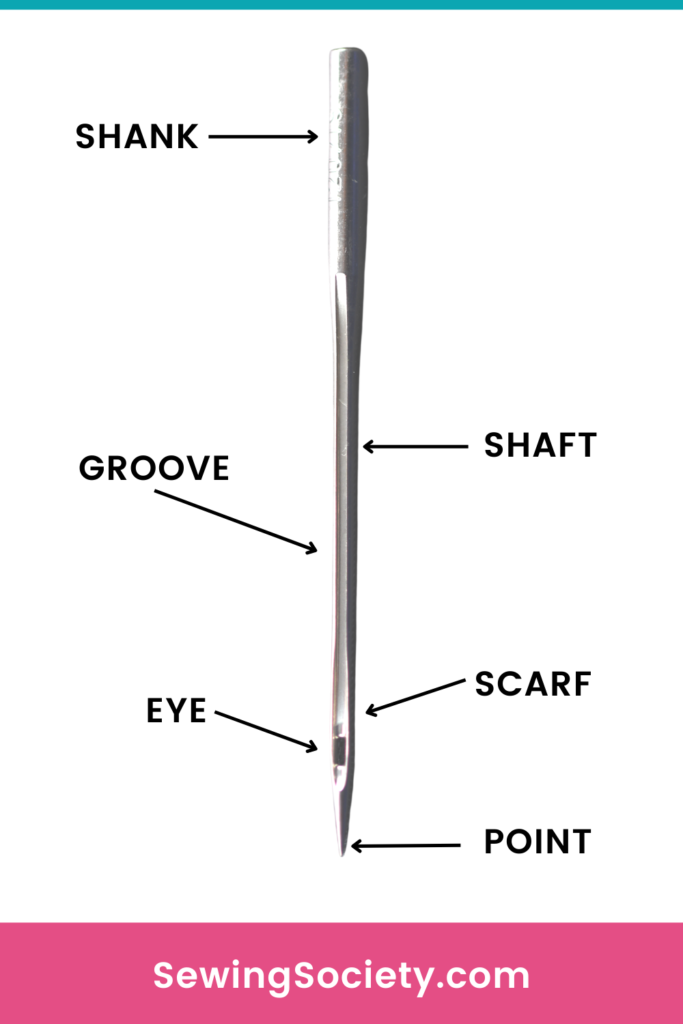

Sewing Needle Terminology

Before I get into the different types of needles, and what they are used for, you need to understand the parts of a needle. There are six sections to every needle:

- Shank: This is the top part of the needle. It is rounded on the front side and flat on the back. The difference in shape allows you to guide your needle into your sewing machine correctly. Just remember that the rounded side should face towards you!

- Shaft: This is the longest part of the needle from the bottom of the shank to the very point. Usually, the shaft contains a groove, scarf, and eye.

- Groove: This can be found running down the needle. It is where the thread sits as it runs from the shaft to the needle eye. Different needles can have different sized grooves.

- Scarf: This is another groove that is out of the side of your needle. It allows your bobbin thread to intersect with your upper thread to form your stitches.

- Eye: This is the little hole where your thread goes through. It can also come in different sizes for different threads.

- Point: The is at the very bottom of your needle, and it is what pierces your fabric. The point can come in three different shapes: sharp, ballpoint, or universal.

Types of Needle Points

As I just mentioned, there are three types of needle points. Each has its own purpose.

- Sharp Needles: The sharper needle points are meant for woven fabrics. These needles are good for topstitching and sewing straight lines.

- Ballpoint Needles: Ballpoint needles are normally meant for knit fabrics. The ballpoint is meant to glide between the loops instead of puncturing the threads.

- Universal Needles: Universal needles are sharp with a slightly rounded point. They can be used on both knit or woven fabrics, but that doesn’t mean you should always rely on them. If you get snags or skipped stitches, you’ll know you need a different needle.

I like to buy an assortment of different sewing machine needles so I always have what I need on hand. You can buy them fairly cheaply in bulk. Keep in mind that Schmetz is considered a top brand for quality because their manufacturing processes virtually eliminate burs.

Sewing Needle Size Chart

Sewing needles come in different sizes. The higher the number, the thicker the shaft of the needle. In general, you need higher numbers for thicker fabrics.

Needle sizes are listed in both European and American notations. There is typically a number printed on the shank, although it can be hard to see. The American size runs from 8 to 19 and the European size runs from 60 to 120. Needles will have a dash between the two. While most of the time it will have the European listed first, it may also be switched. The two different sizes usually have a slash between them, like this: 75/11.

Note: The European size actually makes more sense, as it correlates with the diameter of the needle. A size 120 needle is 1.2mm, a size 100 needle is a 1mm, a size 90 is a .9mm, and so on.

Here’s a sewing needle size chart that shows what each needle is used for:

- 8/60-9/65 Needles: You would use this thinnest needle with very fine fabrics. These needles work well with silk, chiffon, crepe, gauze, sheer, and nylons.

- 10/70-11/75 Needles: The next needle up is perfect for lightweight fabrics like thin jersey, lightweight cotton spandex, and tricot.

- 12/80-14/90 Needles: These needles are best for medium-weight fabrics like quilting cotton, linen, velvet, elastic, knits, flannel, and jersey.

- 16/100-18/110 Needles: These needles are perfect for heavyweight fabrics like upholstery, corduroy, vinyl, wool, heavy denim, leather, canvas, and oilcloth.

- 20/120 Needles: The thickest needle is for the extra heavy fabric like heavy upholstery and extra heavy denim. If you can’t find this number, look for a ‘jeans needle.’

Specialty Sewing Machine Needles

In addition to the basic sizes, you can also find specialty needles. Here’s a list of the more common ones:

- Stretch Needle: If a ballpoint needle is still leaving skipped stitches on knits, then a stretch needle can help you avoid that.

- Denim Needle: These needles are not just meant for jeans; they can be used on any thick fabric or projects with many layers. These needles are built with a sharp point and a thicker, more sturdy shank.

- Metallic Needle: Metallic needles are made for metallic thread. They have elongated eyes which allow metallic thread and other special threads to pass through without breaking.

- Embroidery Needle: This needle is meant for embroidery thread like rayon, cotton, or polyester. The point of the needle is between a ballpoint and sharp needle and has an oversized eye and groove. The build of the needle helps protect the delicate thread for embroidery.

- Topstitch Needle: These needles have an eye that is twice as big as other needles, which allows thread to pass easily through the eye and prevents fraying of the thread. This needle is great for quilting, as the shank of the needle is strong and sturdy, assuring the needle can go through many layers.

- Leather Needle: The point on leather needles is in the shape of a wedge, which helps penetrate thick, leather fabric.

- Quilting Needle: These needles are built to penetrate multiple layers of fabric. They have a tapered, sharp point.

- Twin Needle: These needles include two separate shafts that are attached to one shank. When in use, this needle creates two rows that are evenly spaced apart. If you use this needle, you need to change your presser foot to a zig zag foot so the two needles have plenty of space to go up and down. These needles are threaded with two separate spools. When looking at the size on these needles, you will see two numbers. The first number is the space between the two needles and the second number is the needle size.

- Hemstitch Needle: Hemstitch needles, also called ‘wing needles,’ have a wide blade on each side of the needle, which spreads the weave of the fabric and makes a hole without tearing the fabric. This needle is used with decorative stitches that can normally be found on the trim of garments or projects.

When to Change Your Sewing Machine Needle

Schmetz recommends that you change your sewing machine needle every 8 hours. That’s hard to track and remember, so I suggest you change your needle at the beginning of every new project. This is also a great way to ensure you are using the right needle for your fabric and thread.

Remember, the needle should match the fabric weight!

Here are a few other indicators that you need to change your sewing machine needle:

- If your thread keeps breaking, it could mean you need a needle with a larger eye.

- If you’re getting skipped or uneven stitches, you may have a needle with the wrong point for your project. If you have a ballpoint, try a sharp point or vice versa.

- If you’re getting large puncture marks, this is a sign that your needle is too large for your fabric. Go with a smaller needle and see if that helps.

- If you hear a popping sound when sewing, either your needle is dull or damaged and needs to be replaced, or you may be working with a ballpoint needle and may need a sharp needle.

Once you understand the sizing and the different types of needle points, it is very easy to pick the correct needle for your project. The easiest way to remember is the thicker the fabric, the larger the needle.

If you found this post helpful, you may like my sewing machine troubleshooting book. You can get it on Amazon: Sewing Machine Problems and How to Solve Them.

Share this post on Pinterest!

2 Comments on “Everything You Need to Know About Sewing Machine Needles”